Introduction:

With the continuous advancement of modern design and technology, curved glass (Hot Bending Glass) is playing an increasingly vital role across various industries. Curved glass not only captivates people's attention with its unique aesthetic design but also meets high-standard application requirements through its exceptional strength, optical performance, and safety. Compared to traditional flat glass, curved glass offers significant advantages in manufacturing processes, performance characteristics, and visual effects, enabling smoother appearances, more immersive display experiences, and superior structural adaptability.

This article will delve into the manufacturing processes, performance features, application areas, and future development trends of curved glass, helping you gain a comprehensive understanding of this indispensable material in industrial design and consumer electronics.

Curved Glass refers to glass products that are formed with specific curvatures by subjecting flat glass to heating, molding, or bending processes under controlled conditions. This groundbreaking processing technology transforms the two-dimensional nature of traditional flat glass, enabling the glass material to exhibit smooth and elegant three-dimensional curved forms. It opens up unprecedented possibilities for product design innovation.

Compared to ordinary flat glass, hot-bent glass can achieve a variety of geometric shapes, ranging from simple arcs to complex double-curved surfaces, according to

design requirements. The minimum bending radius can reach up to 100 times the thickness of the glass. This special processing technique not only fully preserves the original excellent properties of glass, such as transparency and weather resistance, but also provides greater design flexibility and aesthetic appeal for product design.

Curved glass, with its elegant curves and continuous surfaces, breaks through the design limitations of traditional flat glass, becoming a pivotal element in modern industrial design and architectural aesthetics. Compared to flat glass, curved glass can create a more fluid and three-dimensional visual effect, lending products and buildings a sculptural artistry and futuristic feel. These natural curves not only provide a visually soft and harmonious appearance but also eliminate sharp corners and joint seams, enhancing the overall design's integrity and sense of luxury. As a result, curved glass has become one of the core materials in high-end architectural curtain walls, smart home appliances, luxury automobiles, and consumer electronics products.

Curved glass processed through hot bending or cold bending techniques exhibits significantly enhanced mechanical properties compared to ordinary flat glass. The curved shape inherently provides greater resistance to wind pressure, often surpassing that of flat glass by over 30%. This structural advantage not only makes curved glass safer and more reliable in large-scale buildings and curtain wall systems but also effectively disperses stress, reducing the risk of edge damage and extending the service life. Furthermore, a well-designed curvature can improve aerodynamic performance, minimizing wind resistance and reducing wind noise, thereby offering a more comfortable experience for vehicles and outdoor structures.

In terms of optical performance, curved glass offers significant advantages in optimizing light distribution and reducing glare, thereby enhancing overall visual comfort. This characteristic is particularly crucial in high-end display devices and automotive infotainment systems, as it not only improves image display quality but also minimizes reflective interference, delivering a more immersive viewing experience. Additionally, when combined with Low-E coatings or anti-glare treatments, curved glass can significantly reduce infrared and ultraviolet radiation, enhancing energy efficiency and protecting interior spaces from excessive heat. This makes it highly popular in modern green buildings and energy-efficient products.

Curved glass is not only aesthetically pleasing but also excels in safety performance. Through tempering, the surface hardness and impact resistance of the glass can be significantly enhanced, while the application of laminating processes further strengthens its explosion-proof and shatter-proof capabilities, making it widely used in public buildings, transportation, and high-end electronic devices. Moreover, curved glass offers exceptional design flexibility, with modern processes enabling a minimum bending radius of 150mm, and thicknesses ranging from 0.5mm to 19mm. It can be used in a variety of applications, from ultra-thin electronic screens to large-scale architectural curtain walls, meeting virtually any creative design requirement.

The production of curved glass is a sophisticated process that integrates materials science with precision engineering, with rigorous substrate selection marking the starting point. Typically, high-quality float glass is employed as the foundational material. Depending on the intended application, options include ultra-clear glass for superior light transmission, or tempered glass and laminated glass to enhance safety. Meanwhile, functional coated glasses (such as Low-E, anti-reflective (AR), and anti-fingerprint (AF) coatings) are also extensively utilized in high-end fields like energy-efficient buildings and smart displays.

During the heating phase, the glass is fed into a specialized hot-bending furnace for precisely controlled segmented heating. Initially, it is slowly heated to approximately 300°C to eliminate residual stresses within the glass. Subsequently, the temperature is further raised to the softening range of 600°C–700°C, rendering the glass malleable. Throughout the heating process, the temperature control precision can reach ±2°C, ensuring uniform heating of the glass and preventing stress concentration or improper deformation caused by temperature differentials.

Once the glass reaches its softened state, it enters the forming stage.

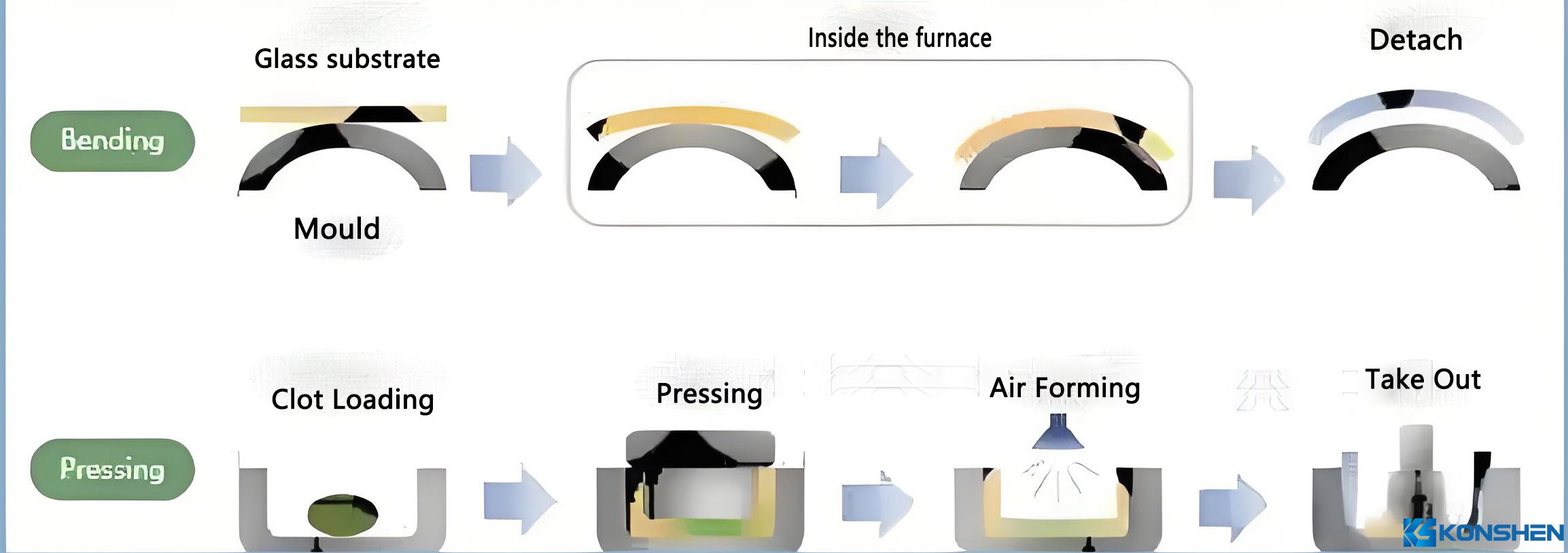

Principle: Glass is heated to its softening temperature and then bent into shape using gravity, molds, or air pressure, followed by cooling to set the form. The detailed processes are as follows:

| Methods | Principle | Advantage | Disadvantage |

| Gravity Bending | Utilizes the self-weight of the glass to naturally bend it over a mold | Simple equipment is required, making it suitable for products with large curvatures and dimensions | Lower precision, limited shape consistency, and longer production cycles. |

| Press Molding | External force is applied to the heated glass through metal or ceramic molds to achieve precise bending. | High forming precision, suitable for products requiring complex curvatures and high consistency. | High mold costs, long development cycles, and best suited for mass production. |

| Air Pressure Forming | Air pressure is applied to the surface of the glass, allowing it to uniformly conform to the mold and form high-precision curved surfaces. | Excellent forming quality, precise curvature control, suitable for 3D complex shapes and high-end display glass. | High equipment investment, complex process, and relatively lower production efficiency. |

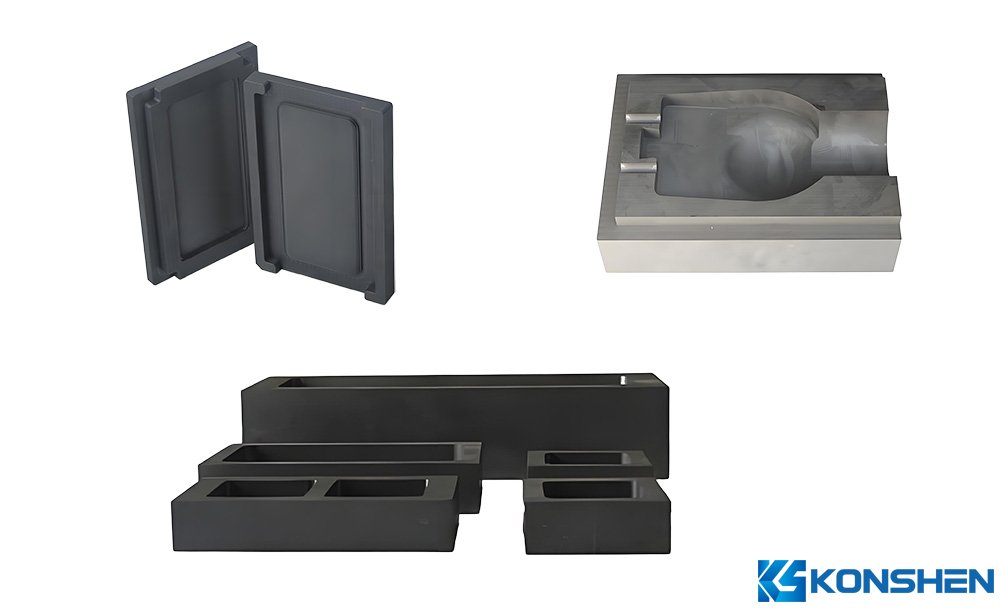

The following is a picture of some graphite moulds:

After the forming process is completed, the glass must undergo annealing treatment to eliminate the stresses generated during processing and ensure long-term product stability. The annealing process requires strict adherence to a cooling curve, with the cooling rate typically controlled at 3 to 5℃ per minute, and the entire process may last several hours. Depending on the final requirements, the glass can also undergo subsequent deep processing, including laminating composite operations, precise edge grinding, and functional coating treatments (such as AR anti-reflection, AF anti-fingerprint, and Low-E energy-saving films), to further optimize its performance and aesthetic appeal.

Curved glass can be strengthened through two main methods:

Physical Tempering (Thermal Tempering): The curved glass is reheated to near its softening point and rapidly cooled to create a surface compression layer. This process significantly enhances mechanical strength and thermal shock resistance, making it ideal for thicker sections or applications requiring high safety performance. Physically tempered glass typically breaks into small, blunt particles, reducing injury risk. However, it may introduce slight optical distortion or warpage, especially in thin or tightly curved shapes.

Chemical Strengthening (Ion Exchange): The curved glass is immersed in a molten salt bath at temperatures below its strain point, replacing smaller ions (such as Na⁺) with larger ones (such as K⁺) in the surface layer. This produces a deep, uniform compression layer without significant deformation, making it particularly suitable for ultra-thin, high-precision curved glass used in consumer electronics. While offering excellent scratch resistance and maintaining surface accuracy, chemical strengthening is more costly and generally less tolerant to extreme heat compared to physical tempering.

Comparison of Strengthening Methods for Curved Glass

|

Aspect |

Physical Tempering (Thermal) |

Chemical Strengthening (Ion Exchange) |

|---|---|---|

|

Applicable Thickness |

Medium to thick glass (≥2mm) |

Ultra-thin glass (0.2-2 mm) |

|

Strength Improvement |

High mechanical and thermal shock resistance |

High surface hardness |

|

Surface Accuracy |

Slight distortion or warpage possible |

Maintains excellent flatness and curvature precision |

|

Optical Performance |

Possible minor optical distortion |

Minimal distortion, better for display covers |

|

Heat Resistance |

Excellent (higher operating temperatures) |

Moderate (lower tolerance to extreme heat) |

|

Breakage Pattern |

Small, blunt particles (safe) |

Irregular fragments (varies by composition) |

|

Cost & Production |

Lower cost, high throughput |

Higher cost, longer process time |

|

Typical Applications |

Architectural glass, lighting covers, safety glazing |

Mobile device covers, high-end curved displays, optical-grade panels |

The choice between these two strengthening methods depends on factors such as glass thickness, curvature radius, optical requirements, thermal performance needs, and safety standards. In practice, a combination of precision bending, annealing, and either physical or chemical strengthening is often used to achieve optimal performance and aesthetics.

With its unique curved characteristics and exceptional performance, bent glass is demonstrating irreplaceable value across an increasing number of fields.

4.1 Automotive IndustryIn the field of transportation manufacturing, bent glass also plays a crucial role. The automotive industry has a particularly prominent demand for bent glass. The front and rear windshields must meet stringent aerodynamic performance and safety requirements, ensuring clear driving visibility while guaranteeing passenger safety in the event of accidents. High-speed train windows employ special bent glass processes to meet the unique structural demands of high-speed operation. Aircraft portholes feature precisely curved designs to withstand the significant pressure differentials encountered during high-altitude flight. These applications fully demonstrate the technological value of bent glass. |

|

4.2 Comsumer ElectronicsThe consumer electronics sector is emerging as a new market for bent glass applications. Curved screens on smartphones, achieved through bent glass technology, offer a more comfortable grip and an immersive visual experience. Smartwatch covers utilize bent glass for both aesthetic appeal and durability. Virtual reality device lenses increasingly adopt bent glass to provide a wider field of view and a more realistic experience. These consumer electronics products impose extremely high requirements on the precision and optical performance of bent glass. |

|

4.3 Medical FieldIn the medical and healthcare field, bent glass demonstrates unique advantages. Observation windows in medical equipment utilize bent glass to provide a clearer field of view and distortion-free observation. Protective shields for laboratory equipment achieve seamless designs through bent glass processes, enhancing safety and sealing performance. Operation panels of high-end medical instruments employ bent glass, offering both aesthetic appeal and ease of cleaning and disinfection. These medical applications impose stringent standards on the purity and chemical stability of the glass. |

|

4.4 Interior Design and Home FurnishThe fields of interior design and home furnishing also benefit from the unique properties of bent glass. Curved shower enclosures significantly enhance waterproofing performance by minimizing seams while creating an elegant bathing space. Spiral staircase railings seamlessly integrate safety requirements with aesthetic pursuits, becoming artistic installations within the space. High-end display cabinets achieve a flawless 360° viewing experience, allowing exhibits to be presented in their entirety. Bent glass is used for kitchen island countertops, offering both aesthetic appeal and ease of cleaning. These applications fully demonstrate the practical value of bent glass in daily life. |

|

As the perfect fusion of modern material science and design aesthetics, bent glass is redefining the morphological language of architecture and products. This technology not only breaks through the form limitations of traditional flat glass but also achieves a harmonious integration of functionality and aesthetics through precise process control. With the continuous advancement of processing technologies and the expanding range of application scenarios, bent glass is bound to demonstrate its unique value in even more fields. This magical craft, capable of transforming rigid materials into graceful curves, is opening a door to a more creative and human-centered future of design. In an era that pursues individuality and experience, bent glass, with its boundless possibilities, continues to infuse human spaces with artistic soul and technological charm.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us